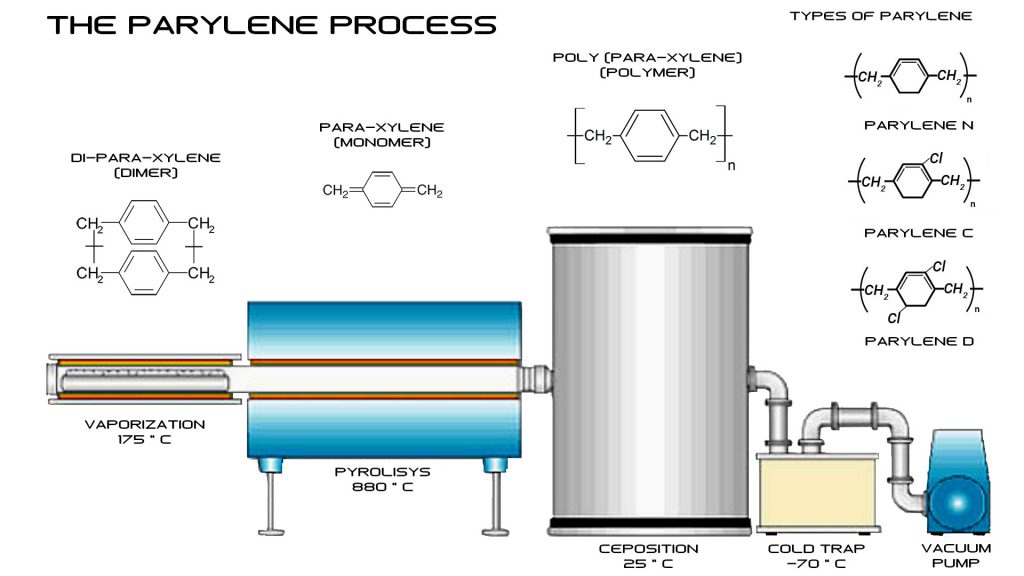

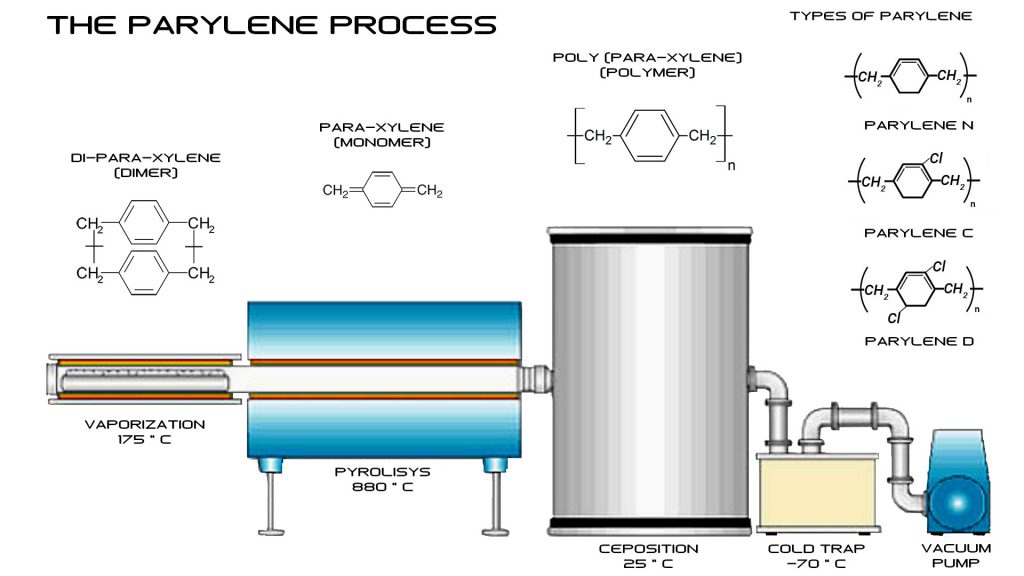

Parylene is a unique vacuum deposition polymer that grows transparent, high-quality, pinhole-free, conformal coatings under vacuum and room temperature. There are several Parylene polymers, including Parylene N, Parylene C, and Parylene F. Each polymer has its own set of material properties and has excellent adhesion to most substrates. These polymers also have excellent chemical resistance and corrosion resistance, high dielectric strength, extremely low moisture and gas permeability, high temperature and UV stability, and biocompatibility, making Parylene become a variety of medical, The coating material of choice for aerospace, military and other industrial coating applications.

The process starts with the particle dimer, weighs out the required material, and then heats it under vacuum to convert it from a solid state to a gas state. The gas is then pyrolyzed at a higher temperature, cracking the dimer into monomer gas. The monomer is then sucked into the room temperature coating chamber, where it is vacuum deposited on the desired substrate surface. Since Parylene is applied in the gas phase, it provides a very satisfactory coating on all uncovered surfaces (including surface cracks), which is far beyond the capabilities of other conformal coating processes (such as dipping or spraying).