parylene

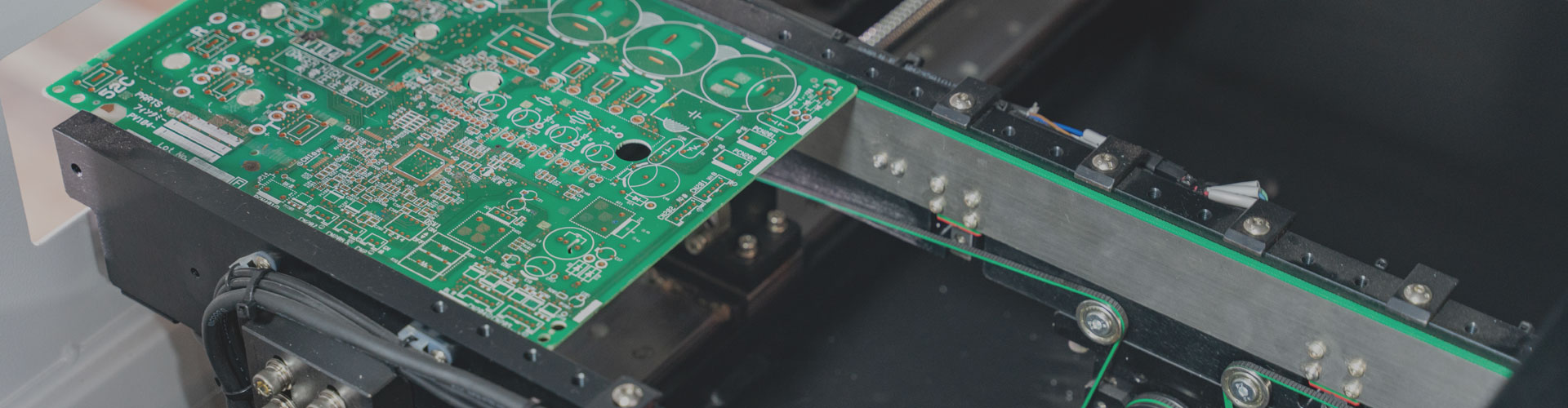

Application on circuit board

With the development of printed circuit components in the direction of miniaturization and high density, new requirements have been put forward for the three prevention measures of printed circuit components. The disadvantages of the traditional three defenses, such as thick and uneven coating, thin coating at corners, insufficient dielectric strength, pinholes and bubbles, are particularly prominent.

Parylene coating belongs to the process of vapor deposition. The gaseous small molecules can penetrate into the small gaps of the components and form a uniform layer of protective film without pinholes and bubbles, which has better moisture-proof, waterproof and corrosion-resistant effects.

In addition, the thickness of Parylene coating is relatively thin (usually 25um), which has little effect on the surface insulation resistance of the circuit board, and it is also very beneficial to the dissipation of heat generated when the components are working. In addition, due to the good symmetry of the molecular structure, it still has a small dielectric loss and dielectric constant at higher frequencies. Its high-frequency and low-loss characteristics make it a reliable protection for high-frequency microwave circuits. condition.